AS/NZS 3760 is an electrical safety standard in Australia that specifies the generally observed safety inspection and maintenance standards. This includes the safety inspection for test

and tag

of single and multiphase portable electrical equipment, and, machinery connected to supply by flexible cord which is currently in-service, returning to service, available for re-sale

or hire.

Inspection and retesting intervals can range from 3 months, 6 months, 12 months, 2 years and up to 5 yearly testing schedules.

As per AS/NZS 3760:2010 electrical safety standard

the law does require that employers, including self-employed, ensure that all electrical equipment they provide in their business is safe and properly maintained.

● Fixed or "hard wired" items

● Items at a height exceeding 2.5mtrs

● Items which need to be dismantled to establish safety of operation

● Demonstration items, sample items or new stock in a retail or warehouse outlet

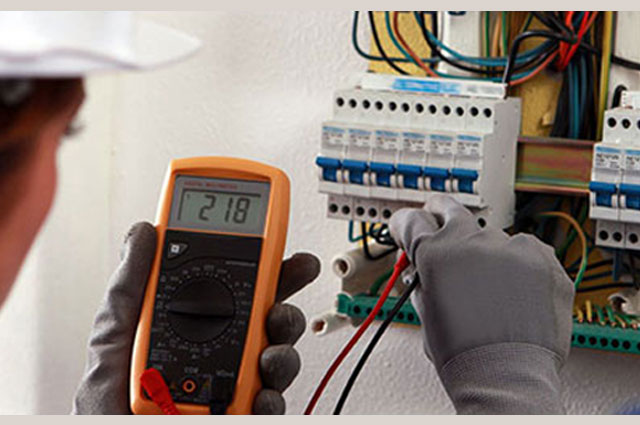

Portable appliance testing (PAT) is the term used to describe the examination of electrical appliances and equipment to ensure they are safe to use as per AS/NZS 3760 electrical safety standard.If you have an appliance that has a plug that is intended to be connected to a wall socket or generator, it qualifies as needing to be PAT tested. This can include items such as electric drills, monitors, printers, Microwaves, PCs, kettles and larger items like photocopiers, vending machines and others. Our technicians use the latest devices to ensure your tools and appliances are safe for use after testing. We provide a detailed report for every item tested and send notification of next scheduled maintenance so you never miss a test and remain compliant. Test reports and asset register are also made available on our Portal for your convenience.

RCD testing is the process of safely "tripping" your RCD to ensure it will operate

quickly should there be an electrical incident. Your RCD is designed to trip, or switch off

all the power to that circuit. In order to ensure your workplace is

compliant under AS/NZS 3760:2010 organisations are required to test their

RCD’s (safety switches) regularly to ensure the devices are working effectively.

Fixed RCD’s :

are installed directly into the switchboard and are the most effective

method of protecting all areas of a home or workplace. They can be installed on all

circuits, or only some circuits depending on site requirements.

Portable RCD’s :

plug in to the socket outlet, and have the ability for portable electrical

items to be plugged in to them, thus protecting the user of the portable electrical item.

These are commonly used where no Fixed RCD’s are present

Socket Outlet RCD’s :

are incorporated in the wall socket outlet. The RCD in the socket

outlet only protects the user of the equipment plugged in to the socket outlet.

Under WHS regulations and AS/NZS 3760:2010, RCD’s are required to be both push

button tested and trip time tested on a regular basis to ensure the device not only

operates as intended, but quickly shuts off power to a circuit in the event of an incident.

Push Button Test :

A push button test is simply testing for operation of the RCD.

If the RCD does not trip (shut off power to the circuit) when the test button is pressed, the

RCD needs urgent replacement as it is not able to perform the function it is intended to.

Trip Time Test :

A trip time test is completed by our electricians or technicians deemed

competent under Australian Standards or state based legislation.Special test equipment

is used to measure the time (in milliseconds) it takes for the RCD to trip when a leakage

to earth is simulated. Australian Standards stipulate the maximum trip time, and should

the RCD not trip within the stated time, the RCD needs urgent replacement as it is not

able to perform the function it is intended to.

According to the AS2293.2 standard for emergency lighting testing & inspection, all emergency lights and exit signs need to be inspected at 6-monthly intervals. During the inspection, a trained technician will test the lamps and replace any defective lights. Each device will also undergo a discharge test in which a technician will turn the battery charger off and simulate a power outage for a duration of 90 minutes.

Microwave Leakage Testing falls under the Australian Standard AS/NZS 60335.2.25 and this is a different procedure from electrically testing a microwave that’s covered under the AS/NZS3760 Standard. The reason for doing this separate test is because radiation has the potential to leak through the door and seals, which in high doses can be harmful to anyone that goes near that microwave oven. Microwave Leakage Testing includes: Physical damage inspection to make sure it is functioning correctly and safely in line with Australian Standards Power outputs of the microwave are operating at sound levels of electrical flow Ensuring your microwave is compliant and safe to use.

According to the AS1851, fire extinguisher test and refill services should occur at the following intervals: All portable and wheeled fire extinguishers need to betested every 6 months. Pressure testing and refills should be carried out at least once every 5 years.

Thermal imaging is a process of viewing heat, generated from an electrical switchboard.

The more power a device draws from a switchboard, or if there is a malfunctioning

component in a switchboard, the more heat that is generated and will therefore be

detected through a thermal image. Infrared cameras are used to capture the thermographic image.

If any of the following areas of concern is present in a switchboard, it can generate

excess heat and stress on the board and can lead to power outage as well as electrical fire.

• Loose terminals

• Undersized cables

• Faulty fuses or circuit breakers

• Incorrectly fitted components

Marindja Facilities Services

PO Box 36120, Winnellie 0821

ABN: 48 618 475 951

Phone : 08 8947 2272 Email: info@marindja.com.au